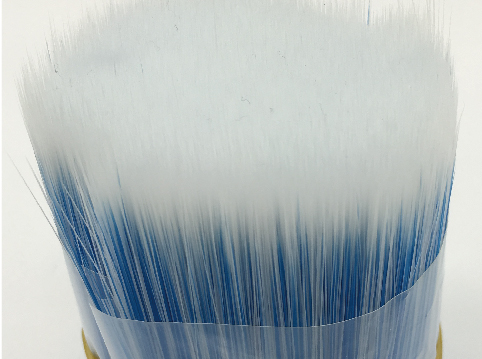

SIC Silicon Carbide Abrasive Nylon PA6 Fiber Wire Brush Filament

PA6 Abrasive Nylon Brush Filament:

PA6 abrasive nylon brush filament is the cheapest one which is very soft and with lower grinding effect. Comparing to other types, PA6 abrasive nylon filament has higher water absorption, but much better bend recovery, excellent toughness, and higher impact resistance. Based on all these characters, PA6 abrasive nylon filament is break-resistant and therefore is often used for dry as well as soft grinding work.

With a melting point of 215℃ and a heat distortion temperature of 190℃, PA6 abrasive nylon filament is suitable for short-time surface finishing, as well as dry grinding under high wheel speed and high pressure. PA6 abrasive filament has bad stiffness in cooling fluid due to its high water absorption. It is better to produce brushes with abrasive filaments with bigger diameter and in higher density. Also, it is better to start trial with small quantity of sample filaments and then issue large order for mass production.

Silicon Carbide (SIC)

Common used abrasive grit is silicon carbide aka SIC grit, which is produced in a resistance type electric furnace with petroleum coke, quartz sand and other materials. SIC is an extremely hard black insoluble crystalline substance. It is used as an abrasive and heat-refractory material and in single crystals as semiconductors, especially in high-temperature applications. Its micro hardness is HV3100-3280, stiffness and hardness is higher than White Alumina. SIC abrasive filament can be widely used to produce industrial brushes for steel, textile, PCB cleaning, stone polishing, and other grinding applications.

Grit Mesh:#36、#46、#60、#80、#120、#180、240、#320、#500、#600、#800、#1000

Grit loading:15%~30%

Diameter: 0.2-2.5mm

Color:Natural,Grey,White,Red,Orange,Blue,etc.

Bundle Diameter:45-51mm

Package:25kg/carton,30kg/carton

HS CODE: 5404190010

Description

SIC Silicon Carbide Grit Abrasive Nylon Polyamide PA6 Bristle Fiber Wire Filament

Abrasive Nylon Brush Filaments:

Abrasive nylon brush filaments are made of nano-particle modified nylon as carrier and 36~1000 mesh abrasive particles such as SIC, AO, and Diamond grinding dust. The hot melts from the above are extruded to form abrasive nylon filaments that are strong and heat resistant under wet or dry conditions.

Application:

Main applications are devices for workplace deburring, grinding, and polishing of the surfaces of steel, stone, and other materials. Also useful for general surface treatment.

-Cleaning Brush (Scrubbing Brush)

-Solid Wood Floor/Furniture Board Brush

-Polishing Brush

-Antique Stone Grinding Brush

-Brush Roll

-Solar Wafer Polishing Brush

-Silicon Rod Polishing Disc Brush

-Grinding Machine Brush

-Industrial Brush

-Wheel Hub Brush

……

Property Comparison Of Nylons:

Bend recovery: PA6<PA66<PA610<PA612

Water absorption: PA612<PA610<PA66<PA6

Durability:PA6<PA66<N610<N612

Comparison Among PA612, PA610 ,PA6:

PA(Nylon) 6 abrasive filament is the cheapest type, which is very soft with the highest water absorption, but very good impact resistance. N6 abrasive filament is suitable for dry and soft grinding work.

PA(Nylon) 610 abrasive filament is very economical type and has been widely used. It is suitable for slow-speed grinding, price-sensitive brushes, rapid-wearing and short-life brushes, such as: industrial brushes for stones, or PCBs.

Property Comparison Of Grit:

The most popular abrasive filaments are SIC and AO filaments. SIC abrasive is generally the best choice for the most of the applications. AO is suitable for precision polishing and soft surface. Basically, every industry has its own common-used abrasive filament. For detailed questions, please do not hesitate to contact us for consulting. It would be more helpful, if you can send us some samples for analyzing.

Silicon Carbide (SIC)

Common used abrasive grit is silicon carbide aka SIC grit, which is produced in a resistance type electric furnace with petroleum coke, quartz sand and other materials. SIC is an extremely hard black insoluble crystalline substance. It is used as an abrasive and heat-refractory material and in single crystals as semiconductors, especially in high-temperature applications. Its micro hardness is HV3100-3280, stiffness and hardness is higher than White Alumina. SIC abrasive filament can be widely used to produce industrial brushes for steel, textile, PCB cleaning, stone polishing, and other grinding applications.

Aluminum Oxide (AO)

AO is a brown crystalline substance that is electrically fused in an arc furnace from a mixture of bauxite at high temperature. The main chemical compound is Al2O3. Its micro hardness is HV1800-2200. And comparing to SIC, AO has less hardness but better toughness. AO abrasive filament is suitable for soft surface and precision work condition, such as: to process copper, aluminum, furniture, and precision parts.

Diamond (DM)

Diamond is the hardest substance found in nature with sharp cutting edges and corners, superior self-sharpening property, and high toughness. The grinding ability is 4 times better than SIC and 10 times better than AO. Due to its expensive price, DM abrasive filament has only been used for super hard material and industry with high added value: such as wolfram steel, silicon plate, expensive jewels.

PA6 Abrasive Nylon Brush Filament:

PA6 abrasive nylon brush filament is the cheapest one which is very soft and with lower grinding effect. Comparing to other types, PA6 abrasive nylon filament has higher water absorption, but much better bend recovery, excellent toughness, and higher impact resistance. Based on all these characters, PA6 abrasive nylon filament is break-resistant and therefore is often used for dry as well as soft grinding work.

With a melting point of 215℃ and a heat distortion temperature of 190℃, PA6 abrasive nylon filament is suitable for short-time surface finishing, as well as dry grinding under high wheel speed and high pressure. PA6 abrasive filament has bad stiffness in cooling fluid due to its high water absorption. It is better to produce brushes with abrasive filaments with bigger diameter and in higher density. Also, it is better to start trial with small quantity of sample filaments and then issue large order for mass production.

Type:

1、PA6+SIC(Silicon Carbide);

Product Parameters:

Grit Mesh:#36、#46、#60、#80、#120、#180、240、#320、#500、#600、#800、#1000

Grit loading:15%~30%

Diameter:0.2-2.5mm

Color:Natural,Grey,White,Red,Orange,Blue,etc.

Bundle Diameter:45-51mm

Package:25kg/carton,30kg/carton

HS CODE: 5404190010

WELCOME TO CONTACT US

Additional information

| Dimensions | 129 × 29 × 15 cm |

|---|---|

| Item No. | SIC Abrasive Brush Filament |

| Base Material | PA6 |

| Grit | Silicon Carbide |

| Grit Mesh | #36、#46、#60、#80、#120、#180、240、#320、#500、#600、#800、#1000 |

| Grit loading | 15%~30% |

| Diameter | 0.2-2.5mm |

| Color | Natural,Grey,White,Red,Orange,Blue,etc. |

| Length | 1250±10mm |

| Bundle Diameter | 45-51mm |

| Package | Plastic Wrapping Film |

| N.W/Carton | 25KGS |

| G.W/Carton | 26KGS |

| HS Code | 5404190010 |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.